About Embossing Technologies

Embossing Technologies is a consulting company that provides technical advice and expertise about the use of embossing in the manufacture of various products. The company was founded in 1996 by Carl Ingalls, and is located near Philadelphia PA (USA).

The primary consulting expert is Carl Ingalls. Other consultants are engaged as needed, including converting experts.

About Carl Ingalls, Embossing Expert Consultant

I am the founder and owner of Embossing Technologies. I specialize in how embossing affects the physical properties of various products and materials, and especially absorbent paper products.

I joined Scott Paper Company at the beginning of 1978 as a Research Engineer at the worldwide corporate headquarters near the Philadelphia International Airport (PHL). After working on a number of papermaking projects, I joined the Embossing Development Group in early 1983. Over the next 13 years, my focus was on embossing and product development for markets in the Americas, Europe, and Asia. (more detail)

Kimberly Clark acquired (merged with) Scott Paper Company in December 1995. They offered me a position in their R&D facilities in Roswell GA. I declined, and started my own consulting company in February 1996.

As a consultant, I continue to do many of the things I did for Scott Paper Company, and I have since broadened my experience into new areas - new products, new materials, new industries.

About the Technology of Embossing

What Is Embossing. Embossing is something that changes the surface of a material from flat to shaped, so that some areas of the surface are raised relative to other areas (or some areas are recessed relative to other areas). With a thin material, (like paper, film, or foil) the raised areas on one side are usually matched by recessed areas on the opposite side, and vice versa.

Why Emboss. Embossing can change the appearance, feel, and physical properties of a material. It can be used to make a product look either similar to or distinctive from other products. It can make a stiff material feel more pliable. It can increase absorbency. It can improve the way a material works inside of a machine.

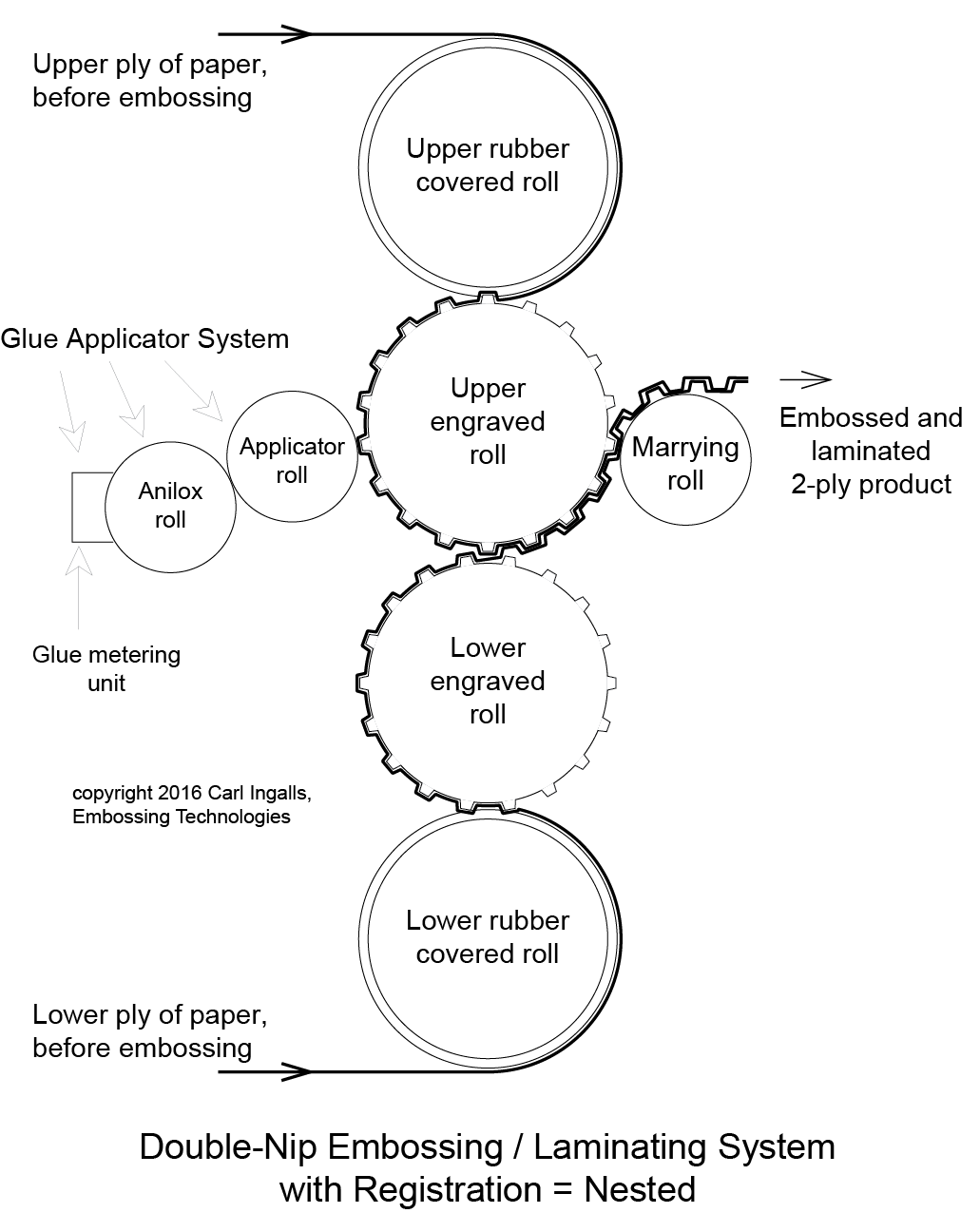

How To Emboss (methods used). For many materials, pressing between two other surfaces (where at least one of those surfaces is shaped) will leave a permanent impression in the material. The other surfaces can be flat plates or they can be cylinders. Flat plates are used with intermittent stamp embossing for materials that are supplied in discrete lengths (cut sheets). Round cylinders are used with continuous rotary embossing for materials that are supplied in much longer lengths (unwound from a roll). This consultancy specializes in continuous rotary embossing with seamless patterns. (more detail)

Terminology. See Glossary of Embossing Terms for definitions.